Tyler Leatherwood, Sage DeFrances, Brandon Kendall, Joe Trisoline and Ross Jubic help make ideas a reality

For a fall semester project, students in the Penn State New Kensington Engineering club are building a 3D printer from scratch; and they are using parts manufactured by a 3D printer they built from a kit during a spring semester project.

Electro-mechanical engineering technology majors Tyler Leatherwood, Sage DeFrances, and Joe Trisoline, engineering major Ross Jubic, and information sciences and technology major Brandon Kendall built the printer as a part of an extracurricular activity for the club. Ron Land, associate professor of engineering, served as faculty adviser for the project.

“We used the popular Mendel Mono do-it-yourself 3D printer kit to build a printer,” said Leatherwood, a product of Kiski Area High School. “We will use the printer we created to print parts for the new printer.”

The project was the brainchild of Leatherwood and DeFrances, president and vice president, respectively, of the Engineering club. Both were interested in how 3D printers worked and anxious to get into the details. Their idea was to help fellow students with engineering projects or hobbies.

“The main purpose of the printer is to make engineering designs a reality,” said DeFrances, a graduate of Greensburg Salem High School. “This can be through prototyping or just simply printing something of interest.”

At the start of the fall 2013 semester, the Engineering club was down to two members, Leatherwood and DeFrances. As a show of solidarity, they elected each other as officers and set about expanding the membership. Using the lure of working with 3D technology, the engineering students set up a booth at Club Rush and signed-up 11 new members. Club Rush is a day during the first week of classes where campus clubs set up booths, talk with new and returning students, and extoll the benefits of participating in extracurricular activities.

“One reason why Tyler and I picked a 3D printer was that it encompasses all the engineering aspects most engineers learn in their first few years of schooling,” said DeFrances, a junior and native of Export, Pennsylvania. “Architectural, electrical, mechanical, civil, and other types of engineering were all involved in building the printer. Motor/printer movement is mechanical, the circuit and wiring work done is electrical, and designing some of the parts on the printer is architectural and civil. Also what every engineer learns in the engineering design course was done by building the main frame of the printer.”

3D manufacturing technology is “additive,” which means making a component by building it up in layers. It’s akin to making a ball of string by continuously winding the string. Classic manufacturing is “reductive,” which means creating something by cutting away parts of it. An example of “reductive manufacturing” would be ice sculpturing. The artist takes a block of ice, and using a chainsaw and chisel, makes a replica of Leonardo da Vinci's “Mona Lisa.”

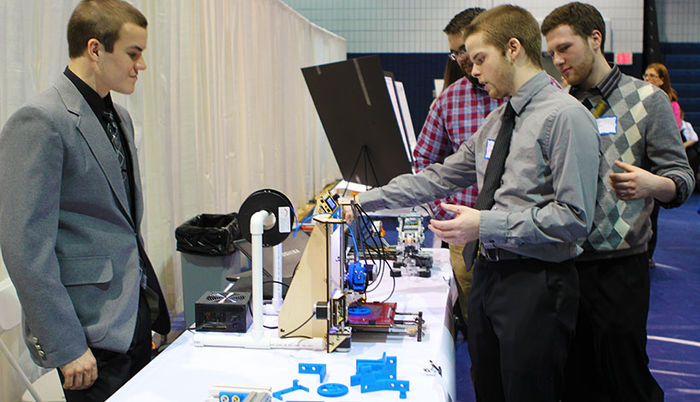

The students showcased their printer in April at the campus’ annual Research and Creative Exposition. The exposition provides students in all majors the opportunity to conduct research, draw conclusions and present their information in a public setting. The engineering students printed a plastic cog-wheel as a demonstration project. The cog-wheel was created thread by thread in about three hours.

“A lot of people have a hard time understanding 3D models created on the computer from software like Solidworks,” said Leatherwood, a native of Heiskell, Tennessee. “What is a better way to explain a model to someone than to print it out and show them.”

The advantage of 3D technology is the ability to produce prototypes in any configuration without building special machining equipment, doing manual processing or making the prototype in parts that have to be assembled. It can be used to produce a single or limited number of items more cost effectively than traditional methods.

“I am in the process of designing prosthetic leg fairing mounts and will use the printer to prototype my ideas,” said DeFrances, who expects to earn a bachelor’s degree in 2016. ”The parts I create in Solidworks could be given to a manufacturer to be made of a more durable material like aluminum or a stronger polymer plastic.”

3D printing also promises to have major impact on inventory management. Instead of warehousing many replacement and repair parts, a company maintains suitable feedstock and a 3D printer to print parts as needed.

"Inventory management becomes a job of maintaining electronic files of parts drawings to drive the printer rather than managing a warehouse full of already built parts of all types," said Land, coordinator of the Electro-Mechanical Engineering Technology program.

While creating a new printer is still in the planning stages, Leatherwood and DeFrances are already working up new projects for the club, such as a modular 3D printer. A modular printer would be able to etch material, draw 2D circuits and machine material. The printer would have detachable parts to make it user friendly.

“Plans of making a filament extruder possibly could occur next year,” DeFrances said. “It would allow us to make the 3D printer plastic material very cheap and would allow us to recycle parts that were made and have no use after prototyping.”

Although 3D printing has been around the scientific community since the ‘90s, advanced technology is bringing it to the mainstream. As new materials are discovered to be printable, there could be no parameters for what can be printed.

“Major research is being done on 3D printing organs,” said Leatherwood, a senior who will graduate in May 2015. “Scientists are already using this technology to print tiny strips of organic tissue."

When not in class or building a 3D printer, Leatherwood can be found working on laser weapons at Penn State’s Electro-Optics Center (EOC). He helps design, test and build components for the high-powered defense systems used by the United States military. Leatherwood earned his position at the center through the campus’ GREAT (Growing Regional Engineering through Academics and Training) program. A collaboration of the New Kensington campus, Electro-Optics Center and industries in the region, GREAT establishes internships at local companies for engineering students. Whereas most internships are geared to juniors and seniors, GREAT interns can begin as soon as their first year in college.

“The internship is an advantage in getting an early start on competition,” said Leatherwood, a resident of Leechburg. “I am getting a feel for the industry while building a resume and building experience.

For selection into the GREAT program, qualified engineering majors go through a competitive interview process with campus faculty and the business partners. Promising students are awarded four-year paid internships that provide opportunities to develop professional skills and gain workplace experience.

Learn more about the GREAT Program program at Penn State New Kensington.

Samantha Polons, Alumna Profile

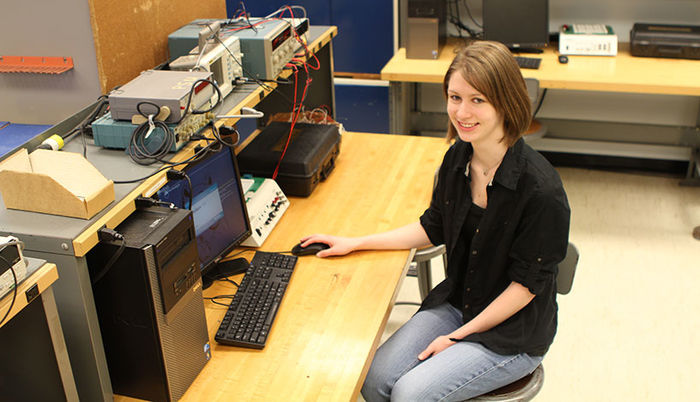

Samantha Polons was selected as the 2012-13 recipient of the Frederick J. Berger Scholarship Award by the Tau Alpha Pi engineering honor society. Polons, now an alumna of the electro-mechanical engineering technology program, was recognized for academic excellence and community service. The $500 scholarship is named after Frederick Berger, founder of the national society for students in engineering technology. Berger endowed the award at Penn State 15 years ago.

“Samantha has consistently excelled in her academics while serving as an officer for not just Tau Alpha Pi, but other clubs on campus,” said Joan Kowalski, senior instructor in engineering and faculty adviser for the society. “She has undertaken several research projects as an honors option and presented her research at the annual Research and Creative Exposition that is held on campus every spring semester.”

Excellence in academics has been Polons’ calling card since arriving on campus in fall 2010. She studies in the Honors program, researches as a member of the campus’ Chancellor’s Fellows program, and interns at Premier Automation in Monroeville. In addition, she works a half-time job during the school year and full-time during the summer. Her community service includes working with WEDIG (Westmoreland Economic Development Initiative for Growth) to help revitalize Westmoreland county.

“I am responsible for a large part of my educational expenses, so the scholarship helps to reduce the amount of student loans and the time I need to work during the semester, so I can spend more time on my classes,” said Polons, a product of Plum High School.

Polons covers tuition with a combination of scholarships, stipends, salary, loans and help from her parents. Despite the workload, she will graduate in May, earning her bachelor’s degree a year ahead of schedule. She carries a 4.0 grade-point average.

“I am trying to minimize the amount of post-graduate debt I will incur,” said Polons, who each year has received the top engineering award for her class. “With this in mind, I have taken heavy credit loads each semester in order to complete my degree in three instead of four years.”

Polons credits the fellowship and internship programs as the incentives for her to enroll at the New Kensington campus to earn an engineering degree. Faculty and staff draw praise for their support of her academic quests.

“I chose Penn State to earn an engineering degree, and the New Kensington campus to provide academic opportunities,” said Polons, an officer for the Engineering and Science student clubs. “The class sizes are small and personal. The teachers are knowledgeable and accommodating, and the assistance with internship opportunities was helpful and abundant. I work hard, but without the help of the teachers and administration, I would not be able to graduate in three years.”

Attending Penn State New Kensington may have been not so much of a choice, as a tradition. The Polons women, Samantha’s mother and two sisters, all attended the campus for two or four years before earning their Penn State degrees. The Polons men, her father and brother, are Penn State alumni but did not follow the New Kensington route, opting instead for four years at the University Park campus.

After graduating in May, Polons hopes to change her classification at Premier Automation from intern to employee. Premier is an engineered solutions company that specializes in providing automation, drive, and electrical control solutions and services to industrial markets.

Branden Citeroni, Alumnus Profile

From securing convoys in Iraq to earning a bachelor’s degree in Upper Burrell to designing automated controls in Washington Township, Branden Citeroni drew upon global and local resources and extracted valuable experiences.

Citeroni, a U.S. Army veteran and Penn State New Kensington alumnus, parlayed his knack for learning and passion for knowledge into a career as an automation engineer for Industrial Automation and Control Inc. His military service as a mechanic charted the course for his degree in engineering. His Bachelor of Science in Electro-Mechanical Engineering Technology was complemented by an internship in his chosen discipline. The internship morphed into a full-time position. Throughout the three-pronged career process -- military, college, vocation – Citeroni utilized experiences in each endeavor to lay the foundation for his vocation.

The Pittsburgh resident served in the Army for four years, including a one-year tour in Iraq in 2005. His unit was in charge of convoy security for base supplies. He rose to the rank of Specialist, or E-4 in Army parlance, and was honorably discharged in 2007.

“My military experience prepared me for an engineering career,” said Citeroni, a mechanic who worked on the unit’s Humvees and five-ton pickup trucks. “The military teaches attention to detail, and I have found that to be a very valuable trait with engineering.”

Armed with the Montgomery G.I. Bill and the Post 9/11 G.I. Bill and an interest in electro-mechanical engineering, Citeroni enrolled at Penn State New Kensington. He chose the New Kensington campus for its small classes, easy access to faculty, and the “real-world” educational opportunities, espoused by campus faculty, which included taking the lessons in the classroom out into the workforce.

“I benefitted from a very hands-on education that prepared me for working very closely with other engineers,” said Citeroni, a native of Latrobe, Pa. “I met a lot of working professionals as well as sales and manufacturing professionals.”

Citeroni also availed himself of the learning resources at the campus, such as Math 97, a one-credit class that provided tutoring and mentoring for all levels of mathematics classes. Mathematics is a staple of engineering classes. In Math 97, Citeroni was given an opportunity to ask questions about concepts from earlier levels of math that were crucial to succeeding in higher-level engineering courses.

“I took the class because I had been out of school for a few years and wanted to brush up on my skills,” said Citeroni, who twice earned the College of Engineering award at the annual Academic and Student Achievement Awards ceremony. “I learned a lot, built a solid mathematical foundation, and finished with the confidence I needed to move forward in the engineering program. Also, the class allowed me to work very closely with my professors and earn their respect.”

"Branden’s perseverance for learning was clearly manifested through the math courses he took with me, including MATH 97,” said Javier Gomez-Calderon, professor of mathematics at the campus.

His engineering acumen landed him an internship with Industrial Automation and Control, a company that brought him onboard after he graduated with distinction in May. Robert “Doc” Mueller, associate professor of engineering at the campus, was the conduit for the internship and the job. Mueller teaches upper-level courses in electro-mechanical engineering and lower-level courses in computer engineering technology, and he is the founder of Industrial Automation and Control, a consulting firm that provides engineering solutions for control system problems. The company is located in the Westmoreland County Business and Research Park on Pennsylvania State Route 780, about four miles from campus.

“I hired Branden as an intern because he was a very good student,” said Mueller, who spent more than 30 years in the private industry working with industrial control systems. “I hired him after he graduated because he demonstrated a great work ethic during his internship and while he was working on his senior project. Smart guys with a great work ethic are hard to beat.”

Citeroni and his wife, Janice, have been married for six years and are active in the community. Both volunteer at Animal Protectors of Allegheny Valley.